Hi Mr Miller

I am sorry to read that you are unhappy with us and I understand the frustration of receiving something you feel you didn't order.

But to be fair to us, we didn't send you something you didn't order. And we do not keep your card details on file.

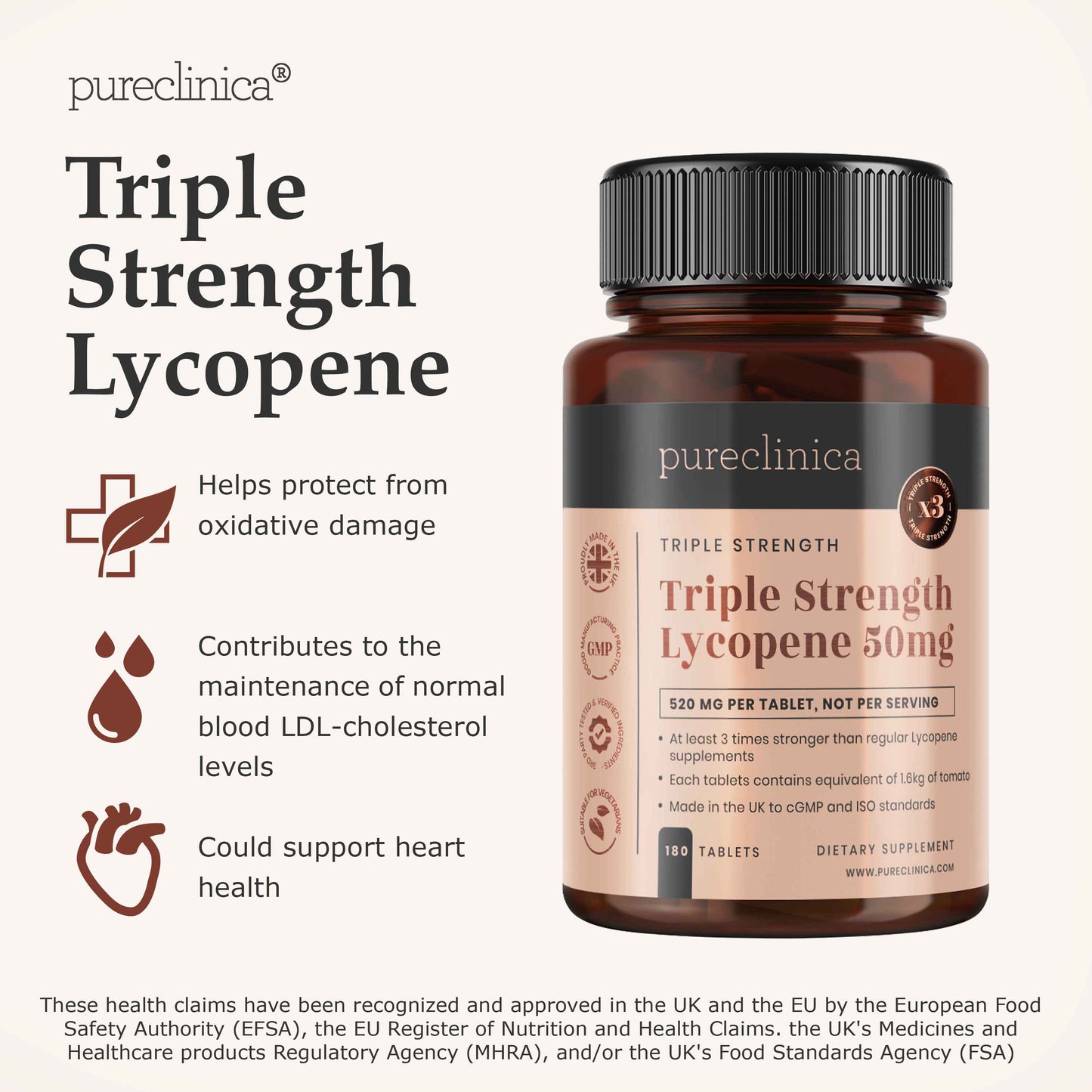

When you placed your order for Lycopene, you did so on a subscription basis. This allowed you to receive a large discount, plus free shipping, but on the condition that you receive at least one refill - also with a discount and free shipping.

In order to place the subcription order, you have to purposefully select the subscription offer on the product page, then select the refill time (30 days, 60 days, 90 days), then confirm you are aware of the subscription and the requirement for at least one refill in a pop up box.

You then have to confirm this a second time at the checkout with it very clearly spelled out.

After purchasing a subscription, you and any customer receives an email with a link to the 'manage subscription' page where the details of your subscription are set out.

A week prior to receiving your refill, you are sent a reminder email of your upcoming subscription order. You are then sent another email 24 hours before dispatch.

All this to say we are not in the business of trying to trick people into re-odering. We offer subscriptions at discounts due to popular demand. It helps our customers who want or need to take their supplements over a long period of time. They can set it up, get a nice discount and free shipping, and forget about it, not having to worry about running out. And it makes it easier for us as a company to maintain long term relationships with our customers and ensure they continue to heal or move towards whatever their health goal might be.

With regards to payment information, the subscriptions we offer are managed by Paypal, and the payment details are kept by paypal, not us. We have no access to, nor have we ever had any access to any customer's payment information. We use only the most commonly used payment processing services, Paypal and Stripe, also used by most online retailers including companies like Zara. These are two enormous payment processors and they absolutely do not allow any company access to the credit card information of anyone. That is a law, it is extremely highly regulated, and we would never want access to customers payment information for our safety and our customers.

It is far better that all of that is handled by a massive company like Paypal. The cost of meeting the enormous security requirements for handling people's payment information is likely in the tens of millions each year.

Again, I am sorry you are unhappy, but you did order a subscription and we simply fulfilled that order.